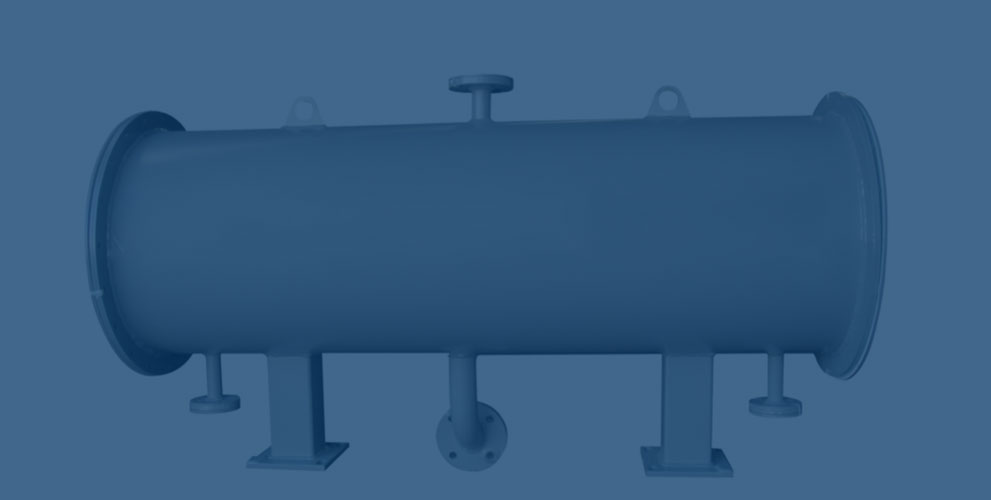

TANKS, COVERS AND CONSERVATORS FOR POWER TRANSFORMERS

All the projects and designs of metal tanks for power transformers are, initially, exhaustively studied by our technical department to define and guarantee that all the parts that compose it and the raw materials acquired meet the quality characteristics that customers demand from us.

The international welding engineer, IWE (International Welding Engineer) carries out the entire welding coordination function edge preparation, welding sequence, tests such as macrographs and breaks, as well as non-destructive tests such as visual inspection.

Tanks, covers and conservators for power transformers

In Fammsa all the welders and operators are qualified respectively according to UNE-EN 287-1 and UNE-EN 1418.

Once the tank has been manufactured, it is inspected with Penetrating Liquids according to EN 517 (level 2) of all the welds made, based on the acceptance criteria according to the UNE-EN 1289 standard.